PTFE (Polytetrafluoroethylene). Have you heard of this name? PTFE is a polymer known for its high non-stick properties and is widely used in various industries. This article focuses on the basic knowledge of PTFE, providing an in-depth explanation of its composition and characteristics. We will explore how PTFE is made, its properties, and the various applications it has. This article is packed with information for those interested in PTFE or looking to gain new knowledge. Let’s dive deep into the world of PTFE together.

PTFE: Basic Overview

Chemical Understanding of PTFE Composition

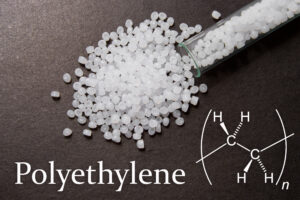

PTFE (Polytetrafluoroethylene) is a type of fluoropolymer, with the chemical formula (C₂F₄)ₙ. This substance is a polymeric compound composed of fluorine atoms and carbon atoms. The characteristic chemical property of PTFE is its extremely stable chemical structure, as the fluorine atoms strongly surround the carbon atoms.

| Component | Description |

|---|---|

| Chemical Formula | (C₂F₄)ₙ |

| Molecular Structure | Long chain-like molecular bonds of alternating carbon and fluorine atoms |

| Bonding Characteristics | Strong, stable carbon-fluorine bonds, highly chemically resistant |

| Chemical Resistance | Resistant to strong acids, strong alkalis, and most chemicals, virtually harmless to many chemical agents |

Chemical Properties:

Fluorine atoms are highly electronegative and form strong bonds with carbon. As a result, PTFE is chemically stable and resistant to most chemicals and solvents.

Chemical Resistance:

PTFE is highly resistant to strong acids, strong alkalis, solvents, and even high-temperature environments. It is widely used in the chemical industry and healthcare sectors.

History and Development of PTFE Resin

PTFE was discovered in 1938 by American chemist Roy Plunkett. He discovered this new material during an experiment with cooling fluorocarbon gases, and soon found it had significant industrial applications.

| Year | Key Events |

|---|---|

| 1938 | Roy Plunkett discovered PTFE, initially as a byproduct of a cooling experiment. |

| 1940s | PTFE was industrialized and began being applied in the chemical, electrical, and mechanical industries. |

| 1950s | Commercial production of PTFE began, expanding the fluoropolymer market. |

| 1960s | PTFE usage increased as an electrical insulator and high-heat material. |

Discovery and Commercialization:

PTFE was initially discovered by accident during a failed cooling experiment. However, its chemical properties were soon recognized, leading to its widespread use across various industries.

Expansion of Applications:

Thanks to its excellent chemical resistance and heat resistance, PTFE has found applications in a wide range of fields, from electronic devices and chemical plants to the food industry and medical equipment.

PTFE continues to evolve, especially due to its high heat resistance, chemical resistance, and insulation properties, replacing many high-performance materials and supporting technological innovations.

Durability and Maintenance of Fluoropolymer Products

Factors Affecting the Durability of PTFE Products

The durability of PTFE (Polytetrafluoroethylene) products is significantly influenced by the operating environment and conditions. Below are the main factors that affect durability.

| Factor | Details |

|---|---|

| Temperature | PTFE has excellent heat resistance, but prolonged exposure to high temperatures can lead to degradation. |

| Chemicals | PTFE is resistant to a wide range of chemicals, but caution is needed with strong acids and alkalis. |

| Wear | Wear due to friction and physical impacts during use can affect the product’s lifespan. |

| Pressure | PTFE is resistant to pressure in high-pressure environments, but excessive pressure can cause deformation. |

| UV Light and Radiation | Prolonged exposure to ultraviolet light or radiation can accelerate PTFE degradation. |

| Mechanical Stress | Repeated mechanical stress (tensile, bending, twisting) can cause PTFE to crack or break. |

When these factors combine, they can reduce the durability of PTFE products. Regular maintenance is particularly important in high-temperature and chemical environments.

Maintenance Methods for Long-Term Use

When using PTFE products for extended periods, proper maintenance can significantly extend their durability. Below are the main maintenance methods.

| Maintenance Method | Details |

|---|---|

| Regular Cleaning | PTFE products are easy to clean. Regular cleaning is important as dirt and chemicals can affect performance. |

| Wear Check | Regularly inspect parts for wear and replace components as needed. High-wear areas (e.g., seals) should be replaced early. |

| Proper Lubrication | Use appropriate lubricants to reduce friction and prevent wear. PTFE is naturally lubricating, but external lubricants may be added if necessary. |

| Temperature Management | For long-term use in high-temperature environments, it is recommended to maintain a consistent temperature or introduce cooling mechanisms to prevent excessive heat degradation. |

| Monitoring for Signs of Degradation | Regularly check for cracks or deformation, especially in areas under pressure, to prevent further damage. |

| UV Protection | To prevent degradation from UV light and radiation, apply UV protective coatings or keep PTFE products out of direct sunlight. |

By regularly implementing these maintenance methods, the lifespan of PTFE products can be greatly extended, preventing performance deterioration. Early detection of issues and maintenance is crucial, especially for products used in harsh environments.

Differences Between PTFE and Other Fluoropolymers

Teflon and PTFE Relationship

PTFE (Polytetrafluoroethylene) is widely known by the trademark name Teflon, which is registered by DuPont in the United States.

In reality, Teflon is the trademark name for PTFE, especially used for products with PTFE coatings (e.g., frying pan coatings).

Comparison with Other Fluoropolymers

There are other fluoropolymers besides PTFE, such as FEP (Fluorinated Ethylene Propylene) and PFA (Perfluoroalkoxy). Below is a comparison of their properties:

| Property | PTFE | FEP (Fluorinated Ethylene Propylene) | PFA (Perfluoroalkoxy) |

|---|---|---|---|

| Heat Resistance | Up to 260°C | Up to 200°C | Up to 260°C |

| Chemical Resistance | Extremely high | High | Extremely high |

| Flexibility | Rigid, brittle | Flexible | Flexible with high processability |

| Molding Difficulty | Difficult, with molding restrictions | Relatively easy to mold | Relatively easy to mold |

| Electrical Insulation | Very high | High | High |

| Cost | High | Moderate | High |

Benefits of Choosing PTFE

Compared to other fluoropolymers, PTFE offers several unique advantages that make it highly favored in various industries:

- Excellent Heat Resistance: PTFE can withstand temperatures up to 260°C, providing stable performance in high-temperature environments.

- Chemical Resistance: PTFE is highly resistant to almost all chemicals, including acids, alkalis, and solvents.

- Low Friction Properties: PTFE has an extremely low coefficient of friction, making it ideal for sliding parts and seals.

- Electrical Insulation: PTFE provides high electrical insulation, making it suitable for use in electrical components.

- Durability: PTFE maintains its performance for extended periods with minimal degradation, making it ideal for long-lasting products.

Given these characteristics, PTFE is particularly preferred in harsh chemical or high-temperature environments. It excels in applications requiring durability and stability.

Fluoropolymer Safety and Environmental Impact

PTFE Health Impacts

Although PTFE is chemically stable, harmful substances that may be released during the manufacturing process or when exposed to high temperatures could pose health risks. Below is a list of the health impacts of PTFE:

- Decomposition at High Temperatures:

- When PTFE is heated above 300°C, toxic gases (fluorinated compounds and tetrafluoroethylene) are released. These gases can be harmful to the respiratory system, and inhaling them may have negative health effects.

- Safety During Normal Use:

- At typical usage temperatures, PTFE remains very stable, posing minimal risk to human health. Even when used in cookware like frying pans, PTFE is considered safe at high temperatures.

PTFE Products and Health Management

- Food-Grade Coatings:

- PTFE coatings used in food-contact items are manufactured following safety regulations, ensuring they are safe for use in food preparation.

- Long-Term Effects:

- When used within normal temperature ranges, PTFE products show no significant health risks, even with long-term use.

Environmental Impact and Sustainability

The production and disposal of PTFE require careful management due to its potential environmental impact. Below is a table showing the environmental concerns associated with PTFE:

| Environmental Impact | Details |

|---|---|

| Chemical Usage During Manufacturing | PTFE production involves the use of fluorinated compounds and chemicals, which may persist in the environment. |

| Fluorinated Compounds Accumulation | Specifically, PFAS (perfluoroalkyl substances) can remain in the environment for long periods, potentially contaminating water sources and soil. |

| Waste and Recycling Difficulty | PTFE is non-biodegradable and remains in the natural environment for extended periods, making recycling challenging. |

Efforts to Reduce Environmental Impact

- Stronger Regulations:

- Many countries have imposed stricter regulations on the use of fluorinated compounds, aiming to minimize their environmental impact.

- Research on Alternative Materials:

- Research into alternative materials and recyclable products is advancing to reduce the environmental effects of PTFE.

Regulations and Standards for Enhanced Safety

PTFE Manufacturing, Use, and Disposal Safety Regulations

The safety of PTFE production, use, and disposal is largely guided by various national and international regulations. Below is a list of relevant regulations and standards:

- REACH Regulation (Europe):

- In the European Union, the REACH regulation monitors the use of chemicals, limiting the emissions of fluorinated compounds during PTFE production.

- Environmental Protection Agency (EPA) Regulations (USA):

- In the United States, the EPA monitors the environmental impacts of PTFE, establishing standards for harmful gas emissions during the manufacturing process.

- Occupational Safety and Health Administration (OSHA):

- OSHA requires that appropriate safety measures be implemented in workplaces where PTFE is used. Ventilation and protective gear are particularly recommended when PTFE is used at high temperatures.

- International Regulations:

- ISO Standards:

- International standards have been established to minimize the safety risks and environmental impact of PTFE, guiding technical practices for its production and use.

- ISO Standards: