Fluororesins are resins with excellent properties such as heat resistance, chemical resistance, and electrical insulation. Due to their diverse characteristics, they are widely used across various fields. This page provides a comprehensive overview of the basics of fluororesins and detailed explanations of the characteristics and applications of seven types of fluororesins. By understanding the unique features of each type, such as PTFE, PFA, and PVDF, you can select the most suitable fluororesin for your needs. If you are considering utilizing fluororesins, this guide will serve as a valuable reference.

Basic Knowledge of Fluororesins

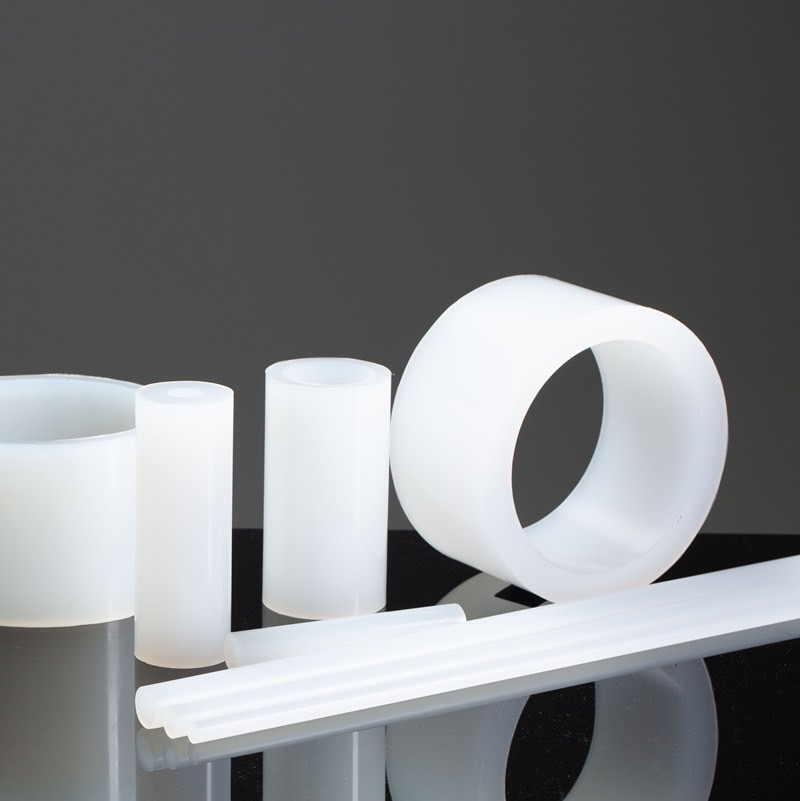

Fluororesins are engineering plastics that exhibit excellent properties such as heat resistance, chemical resistance, and low friction coefficient. Due to the presence of fluorine atoms in the main molecular chain, they possess unique characteristics compared to other organic resins. There are several types of fluororesins, each with distinct properties and applications. Below are the main types:

| Type of Fluororesin | Properties | Primary Applications |

|---|---|---|

| PTFE | Extremely high heat and chemical resistance, non-stick properties | Mechanical components requiring wear resistance |

| PFA | Similar heat and chemical resistance as PTFE, good processability | Piping and valves in semiconductor equipment |

| PVDF | Excellent heat resistance, chemical resistance, and impact resistance, with transparency | Building materials and electrical insulation |

| ETFE | High weatherability and chemical resistance, excellent transparency | Roofs and membrane structures of buildings |

| FEP | High heat and chemical resistance, superior flexibility | Piping and hoses |

Key Points on the Properties and Applications of Each Fluororesin

- PTFE: Its non-stick and wear-resistant properties make it suitable for components where friction is a concern.

- PFA: Offers similar high heat and chemical resistance as PTFE, with added ease of processing, making it valuable in semiconductor manufacturing.

- PVDF: Known for its impact and chemical resistance along with transparency, it is widely used in construction and electrical components.

- ETFE: Due to its high weatherability and chemical resistance, it is increasingly utilized in architectural materials.

- FEP: Balances heat resistance and flexibility, making it ideal for applications requiring pliable piping.

In this way, fluororesins are selected based on their unique properties to match the requirements of specific applications.

Diverse Applications of Fluororesins

Fluororesins are widely used across various fields, from industrial applications to everyday products, thanks to their exceptional properties, including heat resistance, chemical resistance, electrical insulation, and non-stick properties. Below are the primary applications in different fields:

| Field | Main Applications | Fluororesin Properties |

|---|---|---|

| Electrical/Electronic | Printed circuit boards, insulation, capacitors | High insulation, heat resistance |

| Chemical Industry | Piping, valves, pumps for chemical plants | Excellent chemical resistance, corrosion resistance |

| Mechanical Industry | Bearings, seals, sliding components | Low friction coefficient, wear resistance |

| Aerospace | Aircraft and rocket components | Lightweight, superior heat resistance |

| Medical | Artificial joints, blood vessels, medical devices | Biocompatibility, high chemical resistance |

| Consumer Products | Frying pans, pots, water-repellent coatings | Non-stick properties, durability |

Key Points on Fluororesin Applications in Various Fields

- Electrical/Electronic: Fluororesins are ideal for use in electronic components due to their high insulation and heat resistance.

- Chemical Industry: Their excellent chemical resistance makes them suitable for piping and valves in corrosive environments.

- Mechanical Industry: Low friction and wear resistance make fluororesins perfect for bearings and seals in sliding parts.

- Aerospace: Their lightweight and heat-resistant properties are optimal for components used in harsh conditions.

- Medical: Biocompatibility and chemical resistance enable their use in medical devices and implants such as artificial joints.

- Consumer Products: Non-stick properties and durability make them widely used in cookware and water-repellent textiles.

The potential for expanding the applications of fluororesins by leveraging their unique properties continues to grow.

Types and Properties of Fluororesins

Fluororesins are known for their excellent properties, including heat resistance, chemical resistance, electrical insulation, and non-stick qualities. Various types of fluororesins are available to suit specific applications. Below is a detailed explanation of the main types, their properties, and their typical uses.

| Type | Properties | Main Applications |

|---|---|---|

| PTFE | Extremely high heat resistance (maintains performance at 260°C). Very low friction coefficient, excellent chemical resistance, and strong resistance to solvents, acids, and alkalis. Outstanding non-stick properties due to low surface energy. | Bearings, seal components, chemical-resistant tanks, chemical plant piping |

| PFA | Comparable heat and chemical resistance to PTFE but with better processability. High melting point (approx. 310°C) allows for welding and fusing. High transparency and excellent corrosion resistance. | Piping for semiconductor manufacturing, valves, chemical containers |

| FEP | Similar heat and chemical resistance to PTFE (usable up to approx. 200°C). Excellent transparency makes it suitable for visually appealing applications. Flexible and ideal for piping. | Piping, transparent hoses, films, electrical insulation materials |

| ETFE | High weather and chemical resistance with flexibility and impact resistance. Usable at temperatures between 150°C and 170°C. Excellent UV resistance, suitable for outdoor and architectural applications. | Architectural membranes, roofs, greenhouse films, exterior films |

| PVDF | Heat resistance up to 150°C, excellent chemical resistance, mechanical strength, and impact resistance. Superior insulation properties and piezoelectric characteristics, making it suitable for sensor applications. | Chemical plant piping, electrical insulators, pressure sensors |

| PCTFE | High heat resistance (up to approx. 175°C) and chemical resistance. Excellent weather resistance, UV resistance, and transparency. | Medical devices, chemical equipment, vacuum seal components |

| ECTFE | High heat resistance (approx. 150°C) and chemical resistance. Strong impact resistance and excellent processability with high mechanical strength. | Impact-resistant components, pumps, valves, chemical equipment |

Characteristics of Fluororesins

PTFE (Polytetrafluoroethylene)

- Heat Resistance: Stable up to 260°C, with resistance to sudden temperature changes.

- Low Friction: Extremely low friction coefficient, making it ideal for sliding parts.

- Chemical Resistance: Resistant to acids, alkalis, and most solvents, making it particularly useful in chemical plants and industrial components.

PFA (Perfluoroalkoxy Alkane)

- Processability: Unlike PTFE, PFA can be melt-processed, allowing it to be molded into precision parts.

- Chemical Resistance: Resistant to corrosive chemicals, making it ideal for semiconductor and precision equipment piping.

- High Transparency: Offers high transparency, making it useful in applications where the flow of chemicals needs to be visually monitored.

FEP (Perfluoroethylene-Propylene Copolymer)

- Transparency: High transparency, making it suitable for film applications where visibility is important.

- Flexibility: Flexible and can be used in areas where piping or hoses need to bend.

- Heat Resistance: Can withstand temperatures up to 200°C, making it adaptable to a wide range of temperatures.

ETFE (Ethylene-Tetrafluoroethylene Copolymer)

- Weather Resistance: Resistant to UV rays and hot, humid environments, it remains durable even when exposed outdoors for extended periods.

- Flexibility and Impact Resistance: Flexible and resistant to cracking, making it ideal for membrane structures and outdoor film applications.

PVDF (Polyvinylidene Fluoride)

- Mechanical Strength: Strong against pressure and impact, making it suitable for robust structural applications.

- Piezoelectric Properties: Can convert electrical signals, making it useful in vibration and pressure sensors.

- Chemical Resistance and Insulation: Highly resistant to chemicals, it also excels as an insulating material in chemical plants.

PCTFE (Polychlorotrifluoroethylene)

- Weather Resistance: Strong resistance to UV rays and oxygen, and low gas permeability, making it effective in vacuum applications.

- Transparency: High transparency and excellent chemical resistance, making it ideal for applications that require visibility or for medical devices.

ECTFE (Ethylene-Chlorotrifluoroethylene Copolymer)

- Impact Resistance: Tough and impact-resistant, making it ideal for pump and valve components.

- Processability and Strength: Easy to process and used for equipment parts that require high chemical resistance.

Fluororesins each have distinct properties and are used across a wide range of industries, including chemical plants, semiconductors, construction, and medical fields. These materials offer excellent characteristics that can be tailored to specific applications and environments.

What is PTFE (Polytetrafluoroethylene)?

PTFE (Polytetrafluoroethylene) is the most widely used fluororesin, known for its excellent properties such as heat resistance, chemical resistance, electrical insulation, and non-stick characteristics. These qualities make PTFE suitable for a wide range of industrial and everyday applications. Below are the detailed characteristics, advantages, disadvantages, and primary uses of PTFE.

Characteristics of PTFE

- Heat Resistance: PTFE can be used in a wide temperature range from -200°C to 260°C, maintaining performance even in high-temperature environments.

- Chemical Resistance: It has exceptional resistance to many chemical substances such as acids, alkalis, and solvents, making it highly resistant to corrosion.

- Electrical Insulation: PTFE has excellent electrical insulating properties, making it ideal for electronic components and electrical equipment.

- Non-stick: PTFE has low surface energy, which makes it difficult for most substances to stick, and is commonly used in cookware coatings such as frying pans.

Main Uses of PTFE

| Field | Specific Applications |

|---|---|

| Cooking Appliances | Frying pan and pot coatings |

| Chemical Plants | Seals for pipes and valves |

| Electronics/Electrical | Electrical insulation, cable coatings |

| Mechanical Field | Bearings, sliding parts |

| Medical Field | Medical device components (safe for human contact) |

| Semiconductor Manufacturing | Used in piping and joints due to high chemical and heat resistance |

| Aerospace | Aircraft and rocket components |

| Others | Sporting goods, everyday items, etc. |

Advantages of PTFE

- High Heat and Chemical Resistance: PTFE’s ability to withstand extreme temperature conditions and chemicals makes it highly durable.

- Excellent Electrical Insulation: Suitable for electronic and electrical insulation, especially in high-temperature environments.

- Non-stick Properties: Its low surface energy ensures that most substances do not stick, making cleaning easy, ideal for cookware coatings.

- Safety for the Human Body: Biologically inert and safe for use in medical devices that come into contact with the human body.

- Weather Resistance: PTFE is resistant to degradation from UV rays and humidity, making it suitable for long-term outdoor use.

Disadvantages of PTFE

- Difficult Processing: With a high melting point of 327°C, PTFE is difficult to process through melt-forming and requires special processing techniques. Additionally, PTFE is hard and brittle, making it prone to cracking during processing.

- High Cost: PTFE is relatively expensive compared to other fluororesins, increasing the overall cost of products made from it.

Despite its high processing difficulty, PTFE is widely used across industries such as chemical, mechanical, and medical due to its outstanding properties. These factors make it the material of choice for various applications, while its processing challenges are addressed through specialized techniques.

Characteristics of PFA (Perfluoroalkoxy Alkane)

PFA (Perfluoroalkoxy Alkane) shares similar properties with PTFE, but offers enhanced processability and chemical resistance. PFA is highly transparent and flexible, making it suitable for a wider range of applications.

What is PFA (Perfluoroalkoxy Alkane)?

PFA (Perfluoroalkoxy Alkane) is a fluororesin that shares many of the excellent properties of PTFE, but with enhanced processability and transparency. It is widely used in applications that require high chemical resistance, heat resistance, and flexibility. Below are the characteristics, advantages, disadvantages, and primary uses of PFA.

Characteristics of PFA

- Heat Resistance: Like PTFE, PFA has excellent heat resistance and maintains stable performance in high-temperature environments.

- Chemical Resistance: PFA is highly resistant to many chemicals, making it suitable for use in harsh environments.

- Processability: PFA is softer than PTFE, which makes it easier to mold and process, allowing for more complex shapes.

- Transparency: PFA has a high level of transparency, making it ideal for applications where internal visibility is important.

- Flexibility: PFA is flexible and easy to bend or mold, offering greater versatility in design.

Main Uses of PFA

| Field | Specific Applications |

|---|---|

| Chemical Plants | Piping, valves, pumps, and other components requiring chemical resistance |

| Semiconductor Manufacturing | Piping, joint components, valves, etc. |

| Medical Equipment | Tubes, seals, and components requiring high chemical resistance |

| Food Processing Machinery | Parts used in high-temperature and corrosive environments |

| Electronics | Electrical insulation materials and protective coatings for wiring |

Advantages of PFA

- High Heat and Chemical Resistance: PFA maintains stable performance in extreme environments and demonstrates strong chemical stability.

- Ease of Processing: PFA is softer than PTFE, allowing for easier and more complex processing, which gives it greater flexibility in design.

- High Transparency: The high transparency of PFA makes it ideal for applications where internal observation is important, such as in food and medical fields.

- Flexibility: PFA is flexible and can be bent or molded easily, which allows it to be used for piping and complex parts.

PFA combines the high-performance properties of PTFE with improved processability and transparency, making it widely used in various fields such as chemicals, electronics, and medical industries. Its excellent chemical resistance makes it particularly suitable for environments where durability and stability are crucial, and its uses are expected to continue expanding in the future.

What is FEP (Perfluoroethylene Propylene Copolymer)?

FEP (Perfluoroethylene Propylene Copolymer) is a fluororesin with high heat resistance, second only to PTFE. It has a melting point of 260°C and a continuous use temperature of 200°C, making it stable under extreme temperature conditions. Below are the characteristics, advantages, disadvantages, and primary uses of FEP.

Characteristics of FEP

- Heat Resistance: FEP can withstand temperatures up to 260°C and can be used continuously at temperatures up to 200°C.

- Chemical Resistance: FEP is highly resistant to most chemicals and can be safely used in corrosive environments.

- Weather Resistance: FEP is resistant to ultraviolet (UV) light and ozone, making it durable for outdoor use without significant degradation.

- Flexibility: FEP is more flexible than PTFE, making it easier to process and mold into various shapes.

- Transparency: FEP has optical transparency, making it suitable for optical devices and electronic components.

Main Uses of FEP

| Field | Specific Applications |

|---|---|

| Chemical Plants | Piping, valves, pumps, and other components requiring chemical resistance |

| Semiconductor Manufacturing | Connection components, valves, piping, etc. |

| Optical Devices | Lenses, windows, and other parts where optical transparency is needed |

| Electronic Components | Insulation materials and protective covers for electronic parts |

| Food Packaging | Materials used in high-temperature cooking and packaging |

Advantages of FEP

- High Heat and Chemical Resistance: FEP maintains stable performance in extreme conditions, ensuring reliable performance in challenging environments.

- Flexibility: FEP is easy to process, bend, and mold, making it suitable for creating complex shapes.

- Transparency: FEP’s optical clarity is ideal for optical applications and allows for visual inspection of the internal parts.

- Weather Resistance: FEP is durable and resistant to outdoor environmental factors, making it suitable for long-term use in external applications.

Disadvantages of FEP

- Low Wear Resistance: Compared to PTFE, FEP’s surface is more prone to scratching and wear, requiring careful handling in abrasive environments.

FEP takes advantage of its excellent properties to be widely used in various fields, such as chemicals, electronics, and optics. Its high heat resistance, chemical resistance, and transparency make it especially suitable for demanding applications.

What is ETFE (Ethylene Tetrafluoroethylene Copolymer)?

ETFE (Ethylene Tetrafluoroethylene Copolymer) is a fluororesin known for its exceptional weather resistance and transparency. With high strength and excellent chemical resistance, it is widely used in outdoor building materials and industrial products, making it suitable for various applications.

Characteristics of ETFE

- Weather Resistance: ETFE exhibits excellent resistance to ultraviolet (UV) light, heat, and ozone, maintaining transparency and strength for extended periods.

- Transparency: Its light transmission is almost equal to that of glass, making it ideal for roofing materials and greenhouses.

- Lightweight: ETFE is lighter than other fluororesins, making it suitable for creating large membrane structures.

- Chemical Resistance: ETFE is resistant to most chemicals, preventing corrosion and degradation.

- Self-Extinguishing: In the event of a fire, ETFE does not spread flames, ensuring high safety.

Main Uses of ETFE

| Field | Specific Applications |

|---|---|

| Building Materials | Membrane roofing, wall materials, exterior cladding of buildings |

| Industrial Products | Piping, valves, filter materials for chemical plants |

| Sports Equipment | Substrates for artificial turf, outdoor wear |

| Medical Supplies | Artificial blood vessels, artificial organs |

Advantages of ETFE

- Excellent Weather Resistance: ETFE resists degradation from UV rays and chemicals, allowing for long-term use in outdoor environments.

- High Transparency: ETFE allows natural light to pass through, making it perfect for designs that maximize natural lighting.

- Lightweight and Strong: ETFE provides a lighter structure without compromising strength, offering greater design flexibility.

- Self-Extinguishing: ETFE enhances fire safety, preventing the spread of fire and ensuring secure usage.

Disadvantages of ETFE

- High Cost: The manufacturing cost of ETFE is higher compared to other materials.

- Processing Difficulty: Special techniques are required for processing ETFE at high temperatures, making its handling more challenging.

ETFE’s unique properties make it highly suitable for applications in building construction, medical supplies, and industrial equipment. Its combination of weather resistance, transparency, and strength ensures its growing popularity across various industries.

What is PVDF (Polyvinylidene Fluoride)?

PVDF (Polyvinylidene Fluoride) is a fluororesin known for its excellent heat resistance, chemical resistance, and electrical insulating properties. Due to these attributes, it is widely used across various industries.

Main Uses of PVDF

| Field | Specific Applications |

|---|---|

| Building Materials | Roofing materials, exterior wall materials, coatings |

| Chemical Plants | Piping, valves, tanks, and other chemical-resistant materials |

| Electrical & Electronics | Circuit boards, insulating materials, connectors |

| Food Processing | Containers, packaging materials, machine components |

| Pharmaceuticals | Hygienic containers, packaging materials, components for medical devices |

Characteristics of PVDF

- Heat Resistance: PVDF maintains its performance in high-temperature environments, with a high continuous use temperature.

- Chemical Resistance: PVDF shows excellent resistance to strong acids, alkalis, and other harsh chemicals.

- Electrical Insulation: PVDF is non-conductive, making it suitable for use in electronic devices.

- Weather Resistance: It is resistant to UV light and weathering, allowing for outdoor use.

- Biocompatibility: PVDF is safe for contact with food and pharmaceuticals, making it ideal for use in sanitary containers and medical devices.

PVDF’s superior properties make it a versatile material, finding applications in a wide range of industries, from construction and chemicals to food processing and healthcare.

What is PCTFE (Polychlorotrifluoroethylene)?

PCTFE (Polychlorotrifluoroethylene) is a fluororesin known for its excellent chemical resistance, heat resistance, and weatherability. Due to these properties, it is widely used in a variety of industries.

Main Uses of PCTFE

| Field | Specific Applications |

|---|---|

| Semiconductor Manufacturing | High-purity gas and liquid piping, valves, seals |

| Chemical Plants | Piping, valves, pumps, filters, and other chemical-resistant materials |

| Food Processing | Food and beverage contact parts made from food-grade PCTFE |

| Medical Devices | Components for medical devices with excellent biocompatibility |

| Electrical & Electronics | Insulation materials for electronic components with high heat resistance |

Characteristics of PCTFE

- Chemical Resistance: PCTFE has excellent resistance to strong acids and alkalis, making it ideal for use in chemical plants and medical devices.

- Heat Resistance: It maintains its performance even in high-temperature environments and is suitable for long-term use.

- Weather Resistance: PCTFE is highly resistant to UV light and environmental factors, making it suitable for outdoor applications.

- Electrical Insulation: It has high electrical insulation properties, making it an ideal material for insulating electronic devices.

- Biocompatibility: PCTFE is safe for use in the medical field, ensuring compatibility with biological systems.

Thanks to its outstanding properties, PCTFE is expected to be widely used across multiple industries, and demand is anticipated to grow in the future.

ECTFE (Ethylene-Chlorotrifluoroethylene Copolymer) Characteristics

ECTFE is a fluororesin made by copolymerizing ethylene and chlorotrifluoroethylene, and it exhibits excellent properties. Below are its main characteristics and applications.

Characteristics of ECTFE

| Property | Explanation |

|---|---|

| Chemical Resistance | Resistant to most chemicals and solvents, making it ideal for chemical plants. |

| Heat Resistance | Continuous use temperature of 150°C, can withstand up to 200°C for short periods. |

| Flexibility | More flexible than PTFE, easy to bend and process. |

| Impact Resistance | Excellent impact resistance, hard to break. |

| Non-stick Surface | Smooth surface that prevents substances from adhering. |

| Weather Resistance | High resistance to UV light and environmental factors, suitable for outdoor use. |

| Electrical Insulation | High electrical insulation, making it suitable for electronic components. |

Main Applications of ECTFE

- Chemical Plants: Piping, valves, and other chemical-resistant materials.

- Semiconductor Manufacturing: Used for precision components in semiconductor devices.

- Fuel Cells: Components like separators in fuel cells.

- Coatings and Paints: Applications leveraging its non-stick properties.

- Building Materials: Exterior materials utilizing its weather resistance.

ECTFE, with its outstanding properties, is used in various fields such as chemicals, electronics, and construction, and its range of applications is expected to continue growing in the future.

Characteristics and Advantages of Fluororesins

Fluororesins are a general term for resins containing a high amount of fluorine atoms. Key types include PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxyalkane), and PVDF (Polyvinylidene Fluoride), each having distinct characteristics and applications.

Main Advantages of Fluororesins

| Characteristic | Explanation |

|---|---|

| High Heat Resistance | PTFE can withstand continuous use at 260°C, and up to 300°C for short periods, making it suitable for high-temperature environments. |

| Excellent Chemical Resistance | PTFE is resistant to most chemicals, including strong acids and alkalis, making it ideal for use in chemical plants and pharmaceutical manufacturing. |

| High Electrical Insulation | Exhibits excellent electrical insulation properties, widely used in electrical/electronic components and cable insulation. |

| Superior Lubricity | Reduces friction, making it suitable for bearings and sliding parts. |

Challenges

- Difficult Processability: Requires special techniques for processing, making it challenging to handle in certain applications.

- High Cost: Due to high manufacturing costs, it can be economically burdensome.

Fluororesins, with their unique characteristics, provide numerous benefits, particularly in industries requiring high-performance materials. More details on specific types of fluororesins will be discussed in separate articles.

PTFE (Polytetrafluoroethylene) Heat Resistance and Chemical Resistance

PTFE (Polytetrafluoroethylene) is one of the most heat-resistant fluororesins. Below are its main characteristics:

Key Features

| Characteristic | Description |

|---|---|

| High Heat Resistance | Melting point of 327°C and continuous use temperature of 260°C. |

| Chemical Resistance | Resistant to most chemicals, including strong acids and alkalis. |

| Low Friction Coefficient | Slippery and resistant to wear. |

| Non-Stick Properties | Dirt does not adhere, making it easy to clean. |

| Excellent Electrical Insulation | Maintains electrical properties even at high temperatures. |

| Weather Resistance | Resistant to UV rays and ozone. |

Detailed Characteristics

- High Heat Resistance: PTFE has a melting point of 327°C and can be used continuously at temperatures up to 260°C.

- Chemical Resistance: PTFE is impervious to most chemicals and is resistant to corrosion, even from strong acids and alkalis.

- Low Friction Coefficient: Known for its excellent lubricity, PTFE reduces friction and is highly resistant to wear.

- Non-Stick Properties: PTFE’s surface makes it difficult for dirt to adhere, ensuring easy cleaning.

- Excellent Electrical Insulation: It maintains its electrical properties even at high temperatures, making it ideal for use in electrical insulation.

- Weather Resistance: PTFE is highly resistant to ultraviolet (UV) rays and ozone, making it durable for outdoor use.

PTFE’s Heat Resistance and Applications

PTFE is widely used in environments requiring high heat resistance, from -200°C to 260°C, thanks to its unique molecular structure, where strong bonds are formed between fluorine and carbon atoms.

Applications of PTFE’s Heat Resistance

- Cookware: PTFE is commonly used in non-stick pans and cookware due to its high-temperature tolerance.

- Electrical Insulation: It is used in electrical devices as an insulating material, maintaining its properties in high temperatures.

- Chemical Plant Components: PTFE performs well in high-temperature, corrosive environments in chemical plants.

- Medical Field: PTFE is used in biomedical devices such as artificial blood vessels and heart valves.

Detailed Characteristics of Heat Resistance

- Temperature Range: Can be used in a range from -200°C to 260°C.

- Molecular Structure: Strong bonds between fluorine and carbon atoms contribute to its exceptional heat resistance.

- Applications: Cookware, electrical insulation, chemical plant parts, medical devices.

PTFE’s Chemical Resistance

In addition to its heat resistance, PTFE is also highly resistant to chemicals, making it suitable for use in chemical plants and semiconductor manufacturing where aggressive chemicals are involved.

However, PTFE does have some drawbacks, particularly in processing. Its hardness makes shaping and molding difficult, requiring specialized techniques. Additionally, the cost of PTFE can be high.

Challenges

- Difficult Processability: PTFE’s hardness makes molding and shaping difficult, requiring specialized equipment and techniques.

- High Cost: Due to its manufacturing complexity, PTFE is often more expensive than other materials.

PTFE is widely used in demanding environments due to its superior heat and chemical resistance, though its processing challenges and cost must be considered.

Characteristics of Fluoropolymer with High Wear Resistance

Fluoropolymers are known for their excellent wear resistance. The reasons for this include the following points:

- Low Friction Coefficient: Fluoropolymers contain a large number of fluorine atoms on their surface, which results in a very low friction coefficient. This reduces the wear caused by friction.

- High Hardness: Fluoropolymers are among the hardest resins, providing strong resistance to wear and making them difficult to wear out.

- Molecular Structure: Fluoropolymers have a structure in which fluorine atoms and carbon atoms alternate, creating strong molecular bonds that contribute to their resistance to wear.

Due to these characteristics, fluoropolymers are widely used in applications that require high wear resistance, such as bearings, seals, and sliding parts.

Examples of High Wear-Resistant Fluoropolymers

| Resin Type | Features | Applications |

|---|---|---|

| PTFE | Most wear-resistant fluoropolymer | Bearings, seals, sliding parts |

| PFA | High wear resistance and chemical resistance | Chemical plants, semiconductor manufacturing equipment |

| PVDF | High wear resistance and chemical resistance | Pumps, valves, piping systems |

High wear-resistant fluoropolymers are active in various industrial fields. With ongoing research and development, it is expected that even higher-performance fluoropolymers will be developed.

Characteristics of Fluoropolymers with High Non-Stick Properties

Fluoropolymers are highly effective in a wide range of fields due to their excellent non-stick properties. Non-stick properties refer to the ability of a material to smoothly release from a surface without adhering. Fluoropolymers have very low surface energy, meaning they have weak affinity for other substances and do not easily adhere.

This non-stick property is used in various applications. For example, fluoropolymers used in cookware coatings prevent food from sticking and help avoid burning. They are also used as insulating materials in electronic devices to prevent dust and dirt, ensuring the stability of their electrical properties.

Fluoropolymers’ non-stick properties are effective against various substances. They can prevent the adhesion of water, oil, chemicals, and even biological materials. This characteristic is also applied in the medical field, such as in catheters and artificial blood vessels.

Characteristics of Fluoropolymers’ Non-Stick Properties

| Feature | Description |

|---|---|

| Molecular Structure | The structure consists of carbon atoms bonded with fluorine atoms. |

| Low Surface Energy | Fluorine atoms strongly attract electrons, resulting in weak affinity. |

| Applications | Used in cookware, electronic devices, medical devices, etc. |

The non-stick property of fluoropolymers stems from their molecular structure. Fluorine atoms have high electronegativity and attract electrons more strongly than carbon atoms. As a result, the surface of fluoropolymers has a low electron density, reducing the affinity for other materials.

Fluoropolymers’ non-stick properties are widely used in various fields, and their excellent performance is expected to continue to be valuable in the future.

High Non-Stick Properties of Fluoropolymers

Fluoropolymers are widely used in various fields due to their excellent non-stick properties. The surface of fluoropolymers is densely packed with fluorine atoms, which makes it difficult for other substances to bond with them. As a result, substances are less likely to adhere to the surface of fluoropolymers, and any adhered substances are easily removed.

Examples of Fluoropolymer Non-Stick Applications

| Application | Description |

|---|---|

| Food Processing Equipment | Prevents food from sticking, ensuring hygienic use. |

| Anti-Adhesion Materials | Adhesives do not stick, and no residue is left when removed. |

| Sliding Bearings | Low friction, wear-resistant. |

| Water Repellent Coating | Repels water and oil, preventing contamination. |

| Electronic Components | High insulation properties, maintaining stable electrical characteristics. |

Thus, the high non-stick properties of fluoropolymers play an important role in various fields, and further applications utilizing these properties are expected to emerge in the future.

Excellent Insulation Properties of PTFE

Among fluoropolymers, PTFE (Polytetrafluoroethylene) stands out for its superior insulation properties, making it widely used as an insulating material for electrical and electronic devices. The insulation properties of PTFE are attributed to the following factors:

Factors Contributing to PTFE’s Insulation Properties

| Property | Description |

|---|---|

| High Dielectric Constant | PTFE has a high dielectric constant, allowing it to store electrical charge efficiently. |

| Low Dielectric Loss | Very low dielectric loss, enabling transmission without electrical loss. |

| High Voltage Resistance | PTFE has high voltage resistance, making it less prone to insulation breakdown. |

| Non-Absorbent | Does not absorb moisture, preventing electrical conduction. |

| High Heat Resistance | Maintains insulation properties even at high temperatures. |

Due to these excellent characteristics, PTFE is used in various applications as an insulating material.

PTFE’s Weather Resistance and Durability

PTFE (Polytetrafluoroethylene) can maintain its properties even when exposed to harsh environmental conditions such as ultraviolet (UV) rays, heat, rain, and wind. This is due to its non-polarity and low surface energy, which prevents substances like water and oil from adhering to its surface, thus preventing dirt and corrosion.

Additionally, PTFE excels in mechanical strength, wear resistance, and impact resistance. These properties are attributed to its strong fluorine-carbon bonds, which are more robust than other types of bonds, making PTFE resistant to cutting and breaking.

Features of PTFE’s Weather Resistance and Durability

| Property | Description |

|---|---|

| Weather Resistance | Maintains properties even when exposed to UV rays, heat, rain, and wind. |

| Non-Polarity | Prevents substances like water and oil from adhering, avoiding dirt and corrosion. |

| Mechanical Strength | Strong fluorine-carbon bonds make it resistant to cutting and breaking. |

| Wear & Impact Resistance | Resistant to wear and impact, ensuring a long service life. |

PTFE’s Drawbacks and Challenges

While PTFE has excellent properties, it also comes with some drawbacks and challenges. The main challenges include:

Workability Constraints of PTFE

PTFE poses challenges when it comes to processing, particularly for the following reasons:

- Softness: PTFE is relatively soft compared to other fluoropolymers, making it difficult to cut, drill, or process.

- High Melting Point: With a melting point of 327°C, PTFE is challenging to melt and mold like typical thermoplastic resins.

Due to these reasons, manufacturing complex-shaped products can present challenges in terms of processing technology and cost. The primary processing methods are as follows:

| Processing Method | Description |

|---|---|

| Ram Extrusion | A method of extruding PTFE under high temperature and pressure. |

| Sintering | Compressing PTFE powder into molds and sintering it at high temperatures. |

| Dispersion | Dispersing PTFE microparticles in a Teflon dispersion liquid, applying and drying it. |

PTFE: An Expensive Resin

While PTFE offers outstanding performance, it also presents challenges in terms of cost.

Manufacturing Costs

The manufacturing process of PTFE is complex and energy-intensive, leading to high production costs.

Poor Adhesion

PTFE has poor adhesion properties with other materials, requiring special techniques during processing, which further increases costs.

Efforts to Mitigate PTFE’s High Cost

To reduce the high cost of PTFE, the following approaches have been explored:

| Approach | Description |

|---|---|

| Composite Materials Development | Mixing PTFE with other materials to reduce costs. |

| Surface Treatment Improvements | Developing techniques to improve the adhesion properties of PTFE. |

Despite these efforts, the high cost of PTFE remains a significant challenge, and in some applications, other fluoropolymers or alternative materials may be preferred.

Expectations for Overcoming Challenges

With ongoing technological advancements, improvements in PTFE’s processability and cost-effectiveness are expected.

Summary: Properties and Applications of Fluoropolymer Resins

Fluoropolymer resins are plastics that contain a high concentration of fluorine atoms, offering excellent heat resistance, chemical resistance, and non-stick properties. These resins are used in a wide range of industries, and it is essential to select the appropriate type based on their specific properties.

Main Types of Fluoropolymer Resins

| Type | Characteristics |

|---|---|

| PTFE | Excellent heat and chemical resistance, high electrical insulation. |

| PFA | Similar to PTFE in heat and chemical resistance, with better processability. |

| FEP | Excellent heat and chemical resistance, high transparency. |

| ETFE | Excellent weather resistance, high transparency. |

| PVDF | Excellent chemical resistance, impact resistance, good processability. |

| PCTFE | Excellent chemical resistance, impact resistance, high flame retardancy. |

| ECTFE | Excellent chemical and weather resistance, good impact resistance. |

Main Applications of Fluoropolymer Resins

- Electrical insulation materials, seals, gaskets

- Water repellent, anti-fouling, and anti-slip coatings

- Chemical plants, semiconductor manufacturing equipment

- Medical devices, food processing machinery

- Building materials, automotive parts

Due to their exceptional properties, fluoropolymer resins are used in a variety of fields. It is expected that new applications leveraging these properties will continue to expand in the future.